Score Sheet Metal Before Bending Scoring and bending is an easy way to add volume to sheet metal and an invaluable technique in the metalsmith s arsenal This demo focused virtual workshop is an introductory course that will cover the essential tips and tricks behind the process of scoring and bending for the purpose of creating dimension with sheet metal Over two days Ben

In this Tech Tip we will explore the various bend calculation options available for sheet metal namely K Factor bend allowance and bend deduction and guide you on when to use each Scoring metal is incredibly important for custom jewelry construction It enables you to reduce the number of parts in a catch or a hollow piece which increases strength and cuts fabrication time The term scoring refers to creating a groove in metal sheet and then bending it up and soldering it from the back to strengthen the seam

Score Sheet Metal Before Bending

Score Sheet Metal Before Bending

https://xometry.eu/wp-content/uploads/2020/11/Sheet-Metal-Bending-2-scaled.jpeg

An Engineers Guide To Sheet Metal Bending Laser Cutting Komaspec

https://static.komaspec.com/media/prwhkkp4/sheet-metal-bending.jpg

Sheet Metal Bending

https://www.3erp.com/wp-content/uploads/2021/09/sheet-metal-bending-81917-e1632319721816.jpeg

Need to produce a very small radius bend while keeping the outside surface of the bend free of cracking and deformation V grooving could be for you Avoid these seven common pitfalls when designing for sheet metal bending with SendCutSend Use these tips to design proper bends for your parts

As many of you know one way to bend thicker sheet metal without a brake is to score the backside of the sheet at the bending points Freehand scoring V groove bending can establish the bend line and bend angle using grooves cut along the bend line It s also known as score folding V cutting and back scoring The grooving process performed by a separate cutting machine produces a V cut located at the bend line

More picture related to Score Sheet Metal Before Bending

Tips And Tricks For Scoring Metal Ganoksin Jewelry Making Community

https://www.ganoksin.com/wp-content/uploads/2016/07/WireScoring2.png

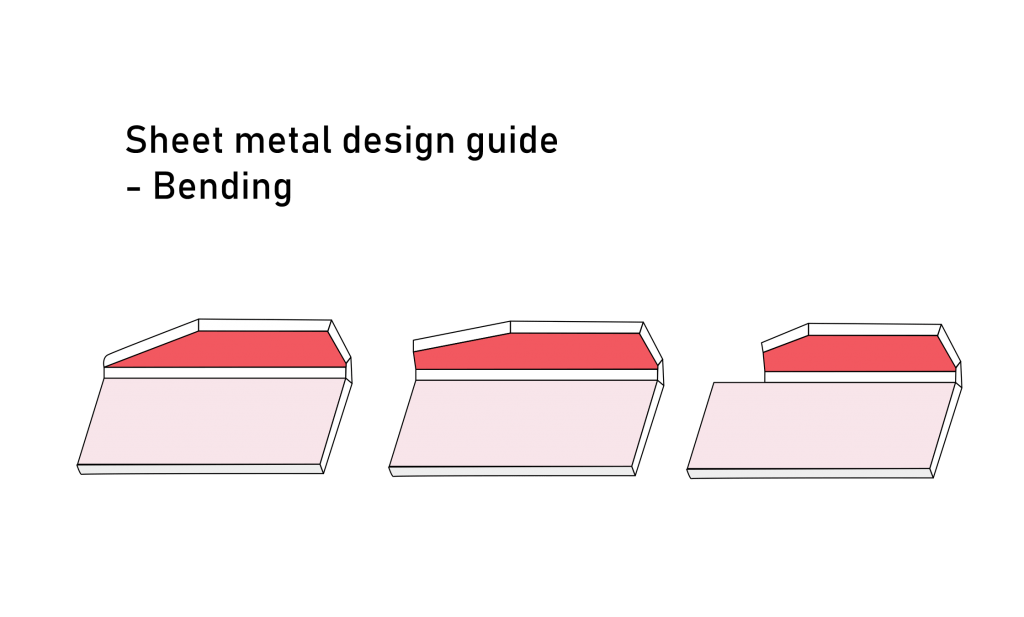

Sheet Metal Fabrication Design Guide Bending

https://www.madearia.com/wp-content/uploads/2022/05/sheet-metal-bending-1024x617.png

The Art Of Sheet Metal Bending Metal Bending Metal Sheet Metal

https://i.pinimg.com/originals/f2/8a/ff/f28afffe0443e4919727ad7e34e3e4d9.jpg

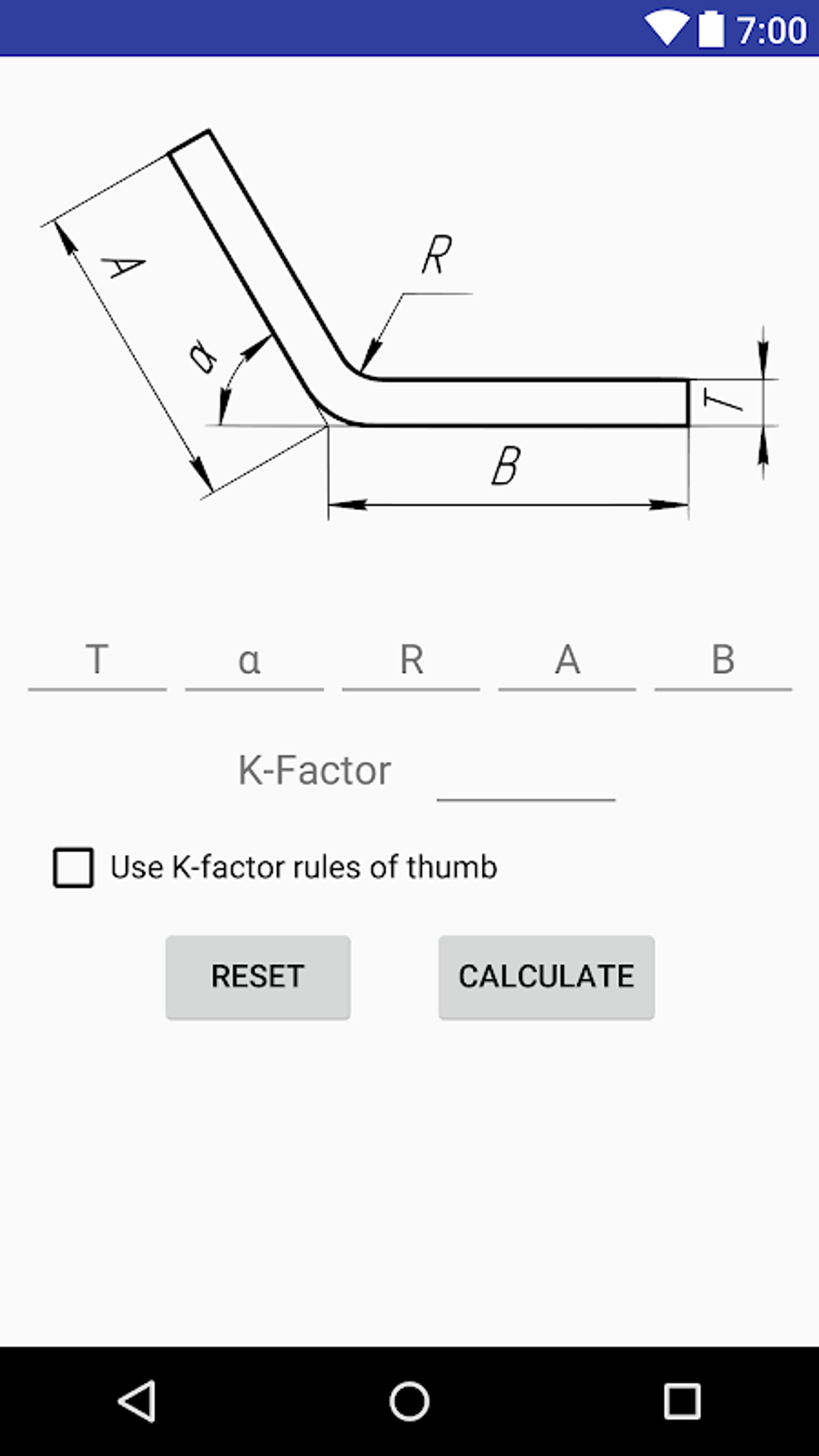

Improve your sheet metal bending techniques with these 8 design guidelines Learn how to create precise bends and avoid costly mistakes In sheet metal bending the K factor is a crucial parameter that determines the amount of material elongation and deformation during the bending process It is a constant value used to calculate the bend allowance which helps determine the final dimensions of the flat sheet before bending

Sheet Metal Bending Calculation Bend Allowance BA BA 0 017453 Inside radius 0 0078 Material thickness Bend angle which is always complementary The length of the neutral axis is calculated as a bend allowance taken at Sheet metal bending can be done using many methods We discuss those along with springback bend allowances k factor design tips etc

03 03 P2 Length Of Starting Blank In Sheet Metal Bending Considering

https://i.ytimg.com/vi/Rp2yvIug46U/maxresdefault.jpg

Sheet Metal Bending In Automobile Manufacturing

https://cdn.thepipingmart.com/wp-content/uploads/2022/12/Metal-Bending-in-Automobile-Manufacturing.png

https://metalwerx.com/class-detail/score-and-bend-1

Scoring and bending is an easy way to add volume to sheet metal and an invaluable technique in the metalsmith s arsenal This demo focused virtual workshop is an introductory course that will cover the essential tips and tricks behind the process of scoring and bending for the purpose of creating dimension with sheet metal Over two days Ben

https://www.onshape.com/.../mastering-sheet-metal-bend-calculations

In this Tech Tip we will explore the various bend calculation options available for sheet metal namely K Factor bend allowance and bend deduction and guide you on when to use each

Sheet Metal Bending Basics Allowances And Tips For Best Results

03 03 P2 Length Of Starting Blank In Sheet Metal Bending Considering

The Sheet Bending

03 03 P5 Calculating Force Required For Sheet Metal Bending YouTube

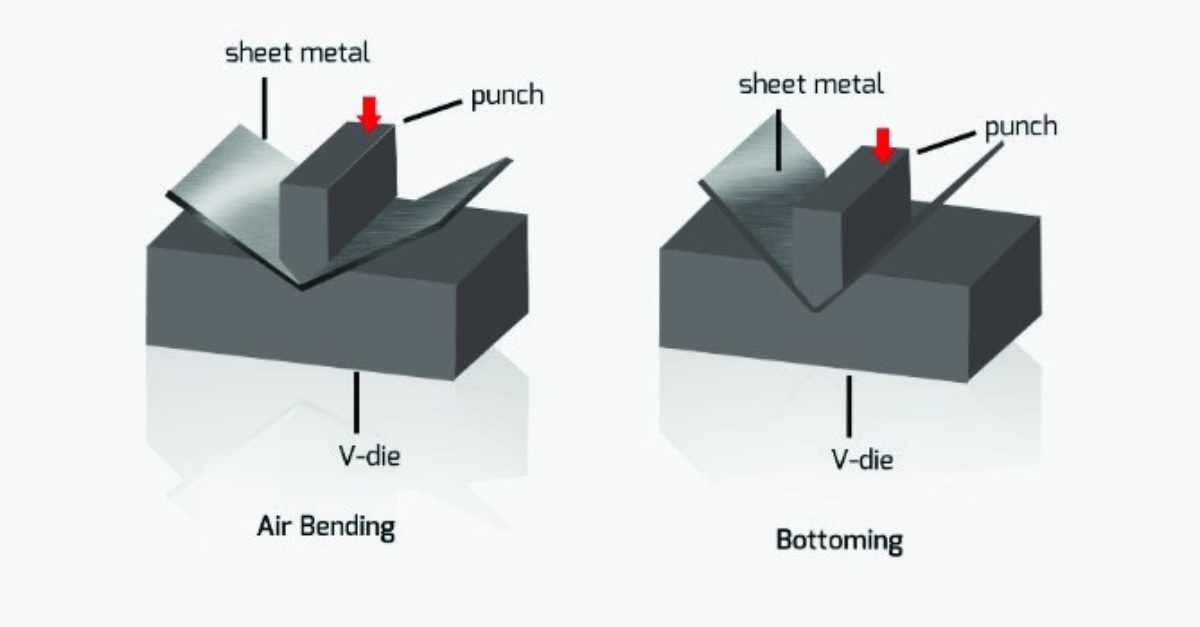

Air Bending And Bottom Bending Sheet Metal Komaspec

Bending Machine 1200 Mm X 2 Mm Sheet Metal Operation YouTube

Bending Machine 1200 Mm X 2 Mm Sheet Metal Operation YouTube

Tips And Tricks For Scoring Metal Ganoksin Jewelry Making Community

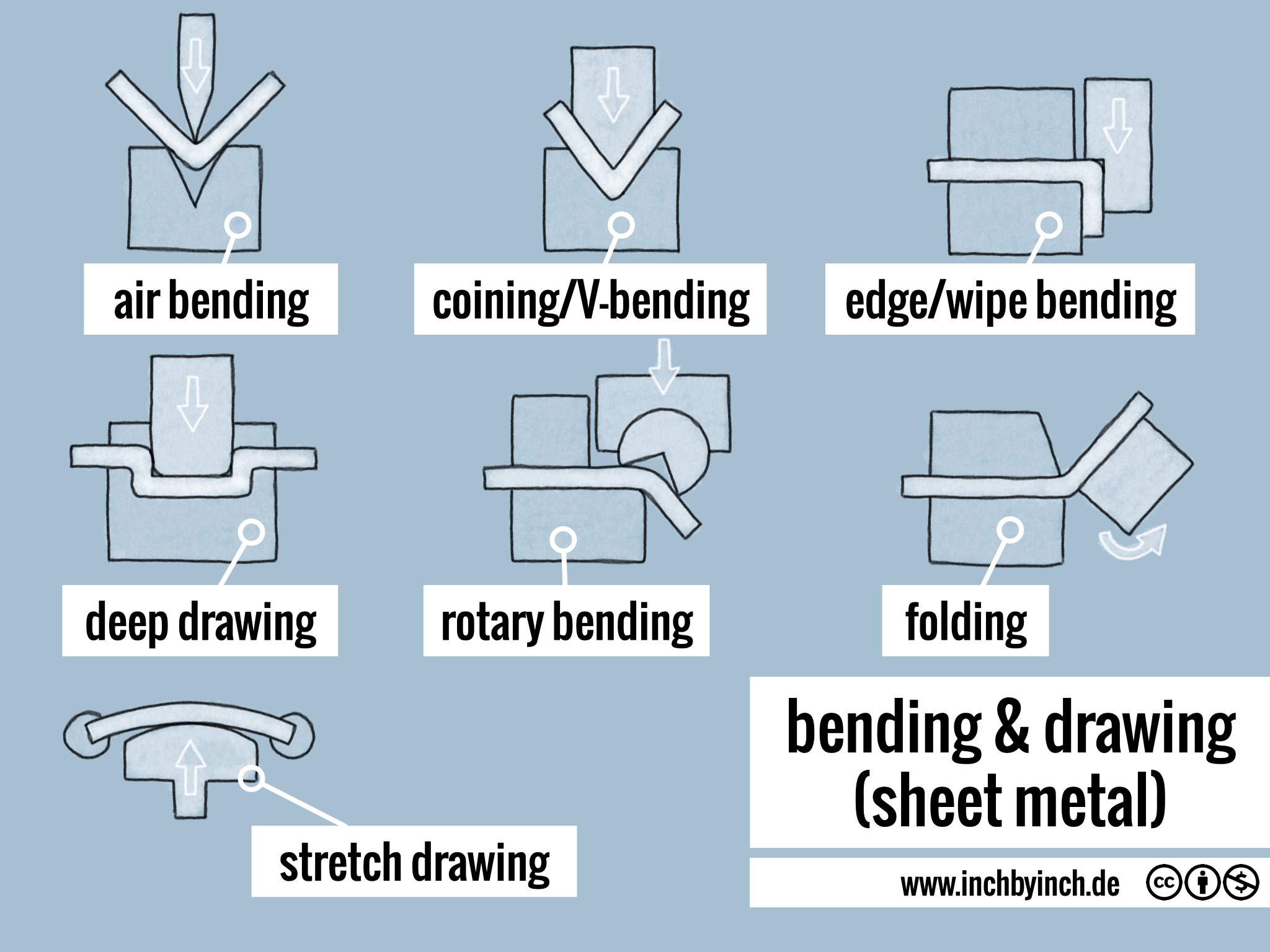

INCH Technical English Pictorial Bending Drawing sheet Metal

Bending Sheet Metal For Android

Score Sheet Metal Before Bending - Bend allowance is key to calculating the length of sheet metal before bending When bending a piece of sheet metal it deforms along the bend radius The outside stretches and the inside compresses Bend allowance allows to account for this change and predict the total length of material needed to get the desired dimensions