Steel Drum Manufacturing Process Flow Chart Steel Production Uses Types The steel industry has grown from ancient times when a few men may have operated periodically a small furnace producing 10 kilograms to

Steel is obtained by refining iron from a blast furnace or scrap steel by the basic oxygen process the open hearth process or in an electric furnace then by removing excess carbon Thus steel could be made away from a source of liquid iron Up to 1950 90 percent of steel in Britain and the United States was produced in the open hearth process and

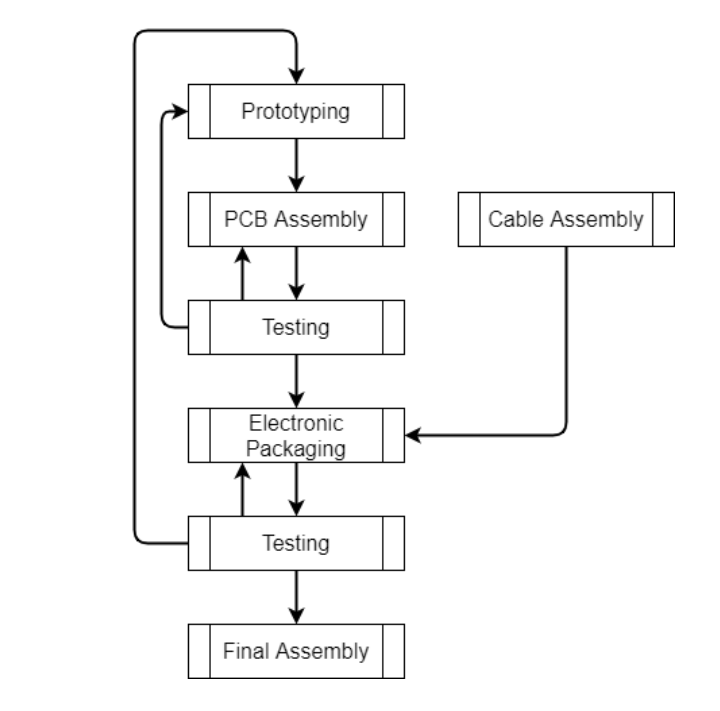

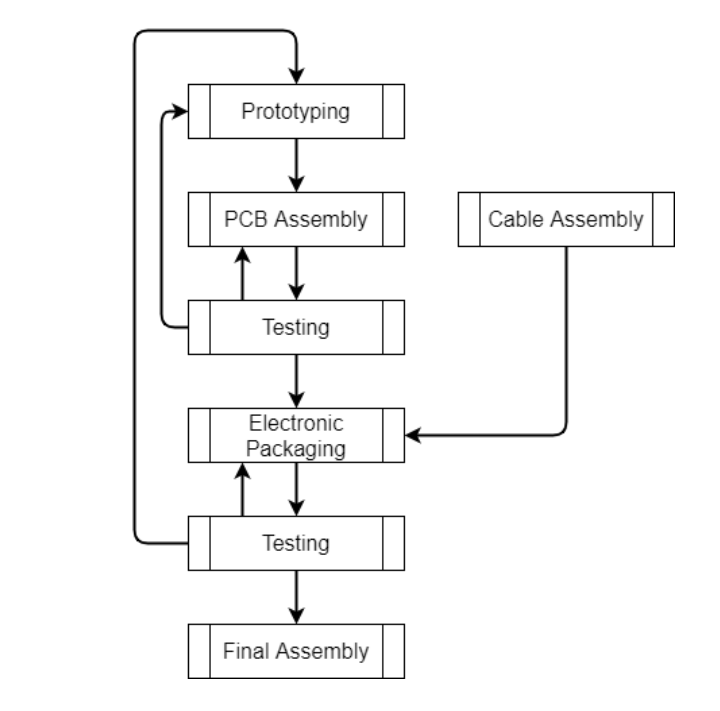

Steel Drum Manufacturing Process Flow Chart

Steel Drum Manufacturing Process Flow Chart

https://i.ytimg.com/vi/P25HxVDgemo/maxresdefault.jpg?sqp=-oaymwEmCIAKENAF8quKqQMa8AEB-AHOBYACgAqKAgwIABABGGUgZShlMA8=&rs=AOn4CLBiDNtc8sLCPpwfSuteEtwxnsut4A

Middle Process Of Steel Drum Manufacturing Line YouTube

https://i.ytimg.com/vi/UeFqES2i_DU/maxresdefault.jpg

Wooden Cable Drum Manufacturing Process Wooden Cable Drum Making

https://i.ytimg.com/vi/r9RNA_8Sku0/maxresdefault.jpg

To make a heat or one batch of steel in an open hearth furnace limestone pig iron and steel scrap are initially dumped into the unit These materials are heated for about two hours until There are more than 100 grades of stainless steel The majority are classified into five major groups in the family of stainless steels austenitic ferritic martensitic duplex and precipitation

Steel Alloying Properties Uses Alloying elements are added to steels in order to improve specific properties such as strength wear and corrosion resistance Steel Smelting Alloying Refining In principle steelmaking is a melting purifying and alloying process carried out at approximately 1 600 C 2 900 F in molten conditions

More picture related to Steel Drum Manufacturing Process Flow Chart

275 Gallon Tote And 330 Gallon Tote Plastic Drum Manufacturing

https://i.ytimg.com/vi/y-6NSK4XLKA/maxresdefault.jpg

Lipstick Manufacturing Process Flow Chart Template Infoupdate

https://online.visual-paradigm.com/repository/images/e169791b-f152-443c-a8bb-0e74532f2b45/flowchart-design/manufacturing-process-flowchart.png

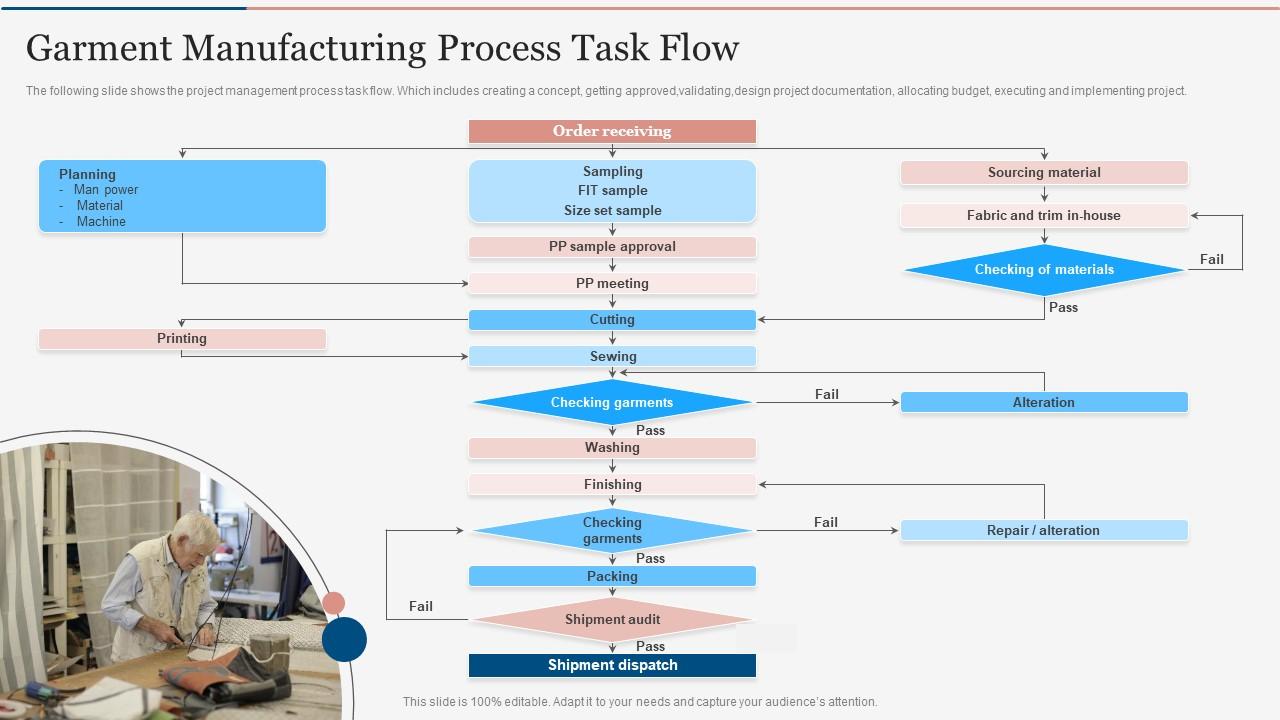

Garment Manufacturing Process Flow Chart 49 OFF

https://www.slideteam.net/media/catalog/product/cache/1280x720/g/a/garment_manufacturing_process_task_flow_slide01.jpg

Steel guitar any of several stringed instruments that are distinguished by being played traditionally on the lap wherein a rigid object typically a metal bar is moved over the strings as the There are several thousand steel grades either published registered or standardized worldwide all of which have different chemical compositions and special

[desc-10] [desc-11]

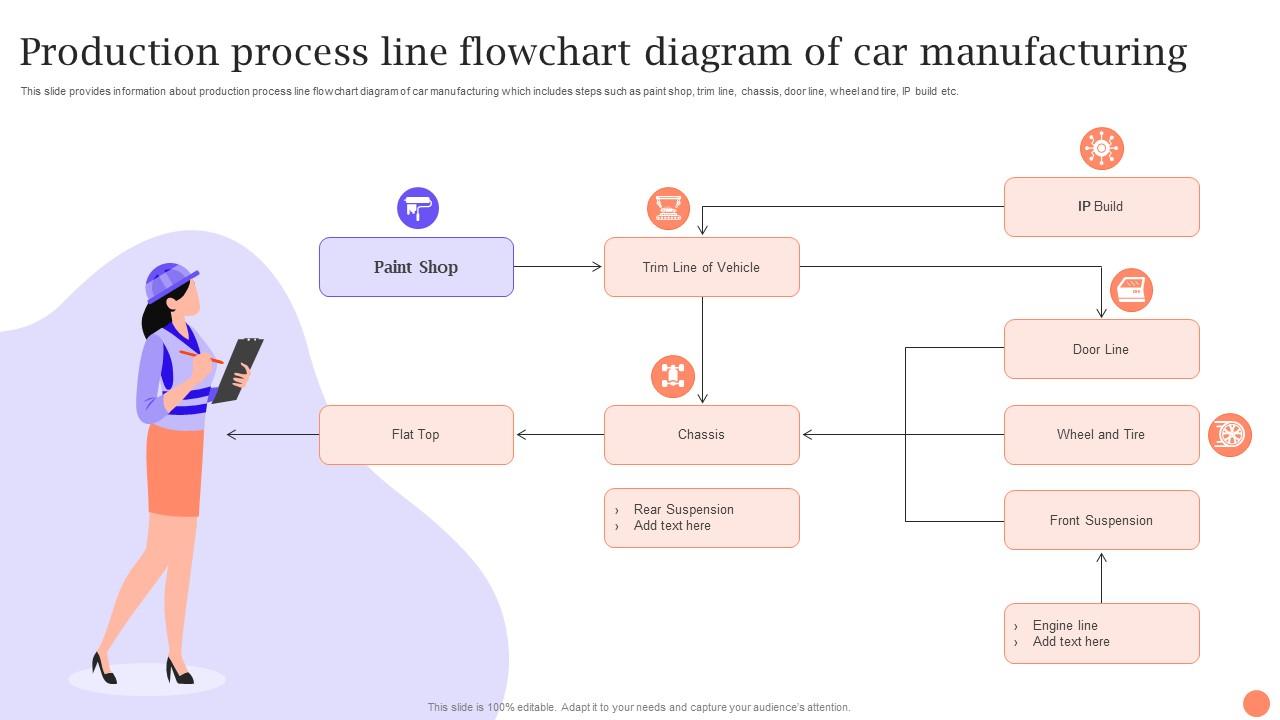

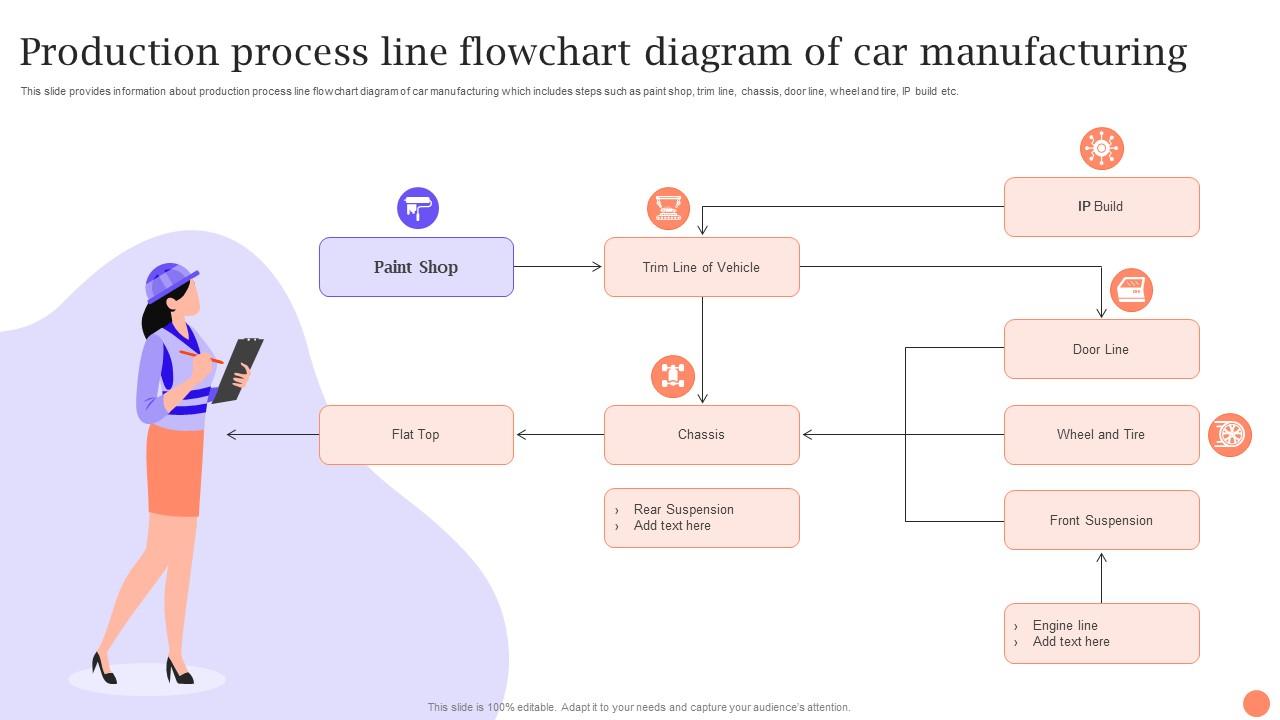

Top 10 Manufacturing Process Flow Charts With Templates 46 OFF

https://www.slideteam.net/media/catalog/product/cache/1280x720/p/r/production_process_line_flowchart_diagram_of_car_manufacturing_slide01.jpg

Cocoa Processing INDCRESA

https://indcresa.com/wp-content/uploads/2023/01/indcresa-cocoa-process-2023.png

https://www.britannica.com › technology › steel › History

Steel Production Uses Types The steel industry has grown from ancient times when a few men may have operated periodically a small furnace producing 10 kilograms to

https://www.britannica.com › summary › steel

Steel is obtained by refining iron from a blast furnace or scrap steel by the basic oxygen process the open hearth process or in an electric furnace then by removing excess carbon

Schutz Container Systems Steel Drum Plant New South Construction

Top 10 Manufacturing Process Flow Charts With Templates 46 OFF

Rotary Drum Vacuum Filters Chemical Plant Engineering CPE

Hot Rolled Steel Coil Processing Sketch Flow Diagram Metal Sheet

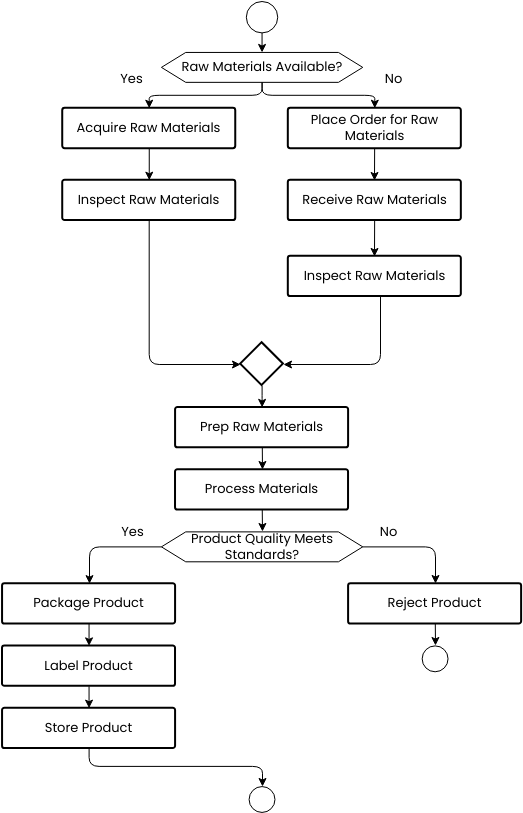

Process Map Process Flow Sales Process Hiring Process Flowchart

Electronics Manufacturing Process

Electronics Manufacturing Process

.jpg)

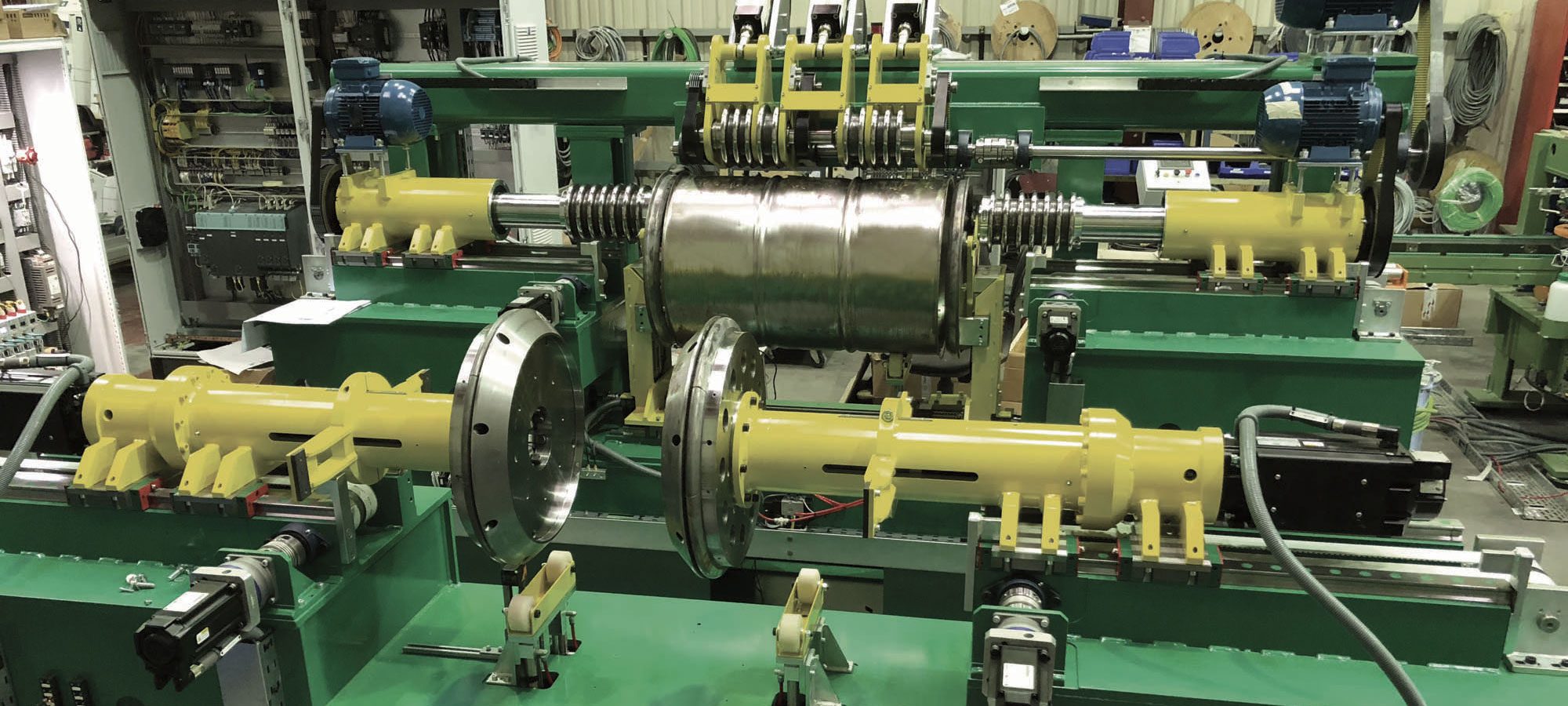

AUTOMATIC DRUM MANUFACTURING LINE

Automotive Company Manufacturing Process Flow Chart PPT Template

Steel Drums Manufacturing Equipment Remy Intl

Steel Drum Manufacturing Process Flow Chart - Steel Smelting Alloying Refining In principle steelmaking is a melting purifying and alloying process carried out at approximately 1 600 C 2 900 F in molten conditions