How To Find The Radius Of A 90 Degree Bend We are going to review three bending scenarios with three different bending angles 60 90 and 120 and we will calculate K Factor Bend Allowance and Bend Deduction for them The bending tool has a radius of 30 mm which

Identify minimum flange length and achievable internal radius Find the minimum flange length suitable for the selected V opening as well as the achievable internal radius for this sheet Assuming a 90 bend and constant radius measure the chord red line between tangent points A and B and divide by the square root of 2 1 414 or multiply by 0 707

How To Find The Radius Of A 90 Degree Bend

How To Find The Radius Of A 90 Degree Bend

https://f.hubspotusercontent30.net/hubfs/4546781/Website 2021 Product Images/Short-Radius-Bend-90-500x500-Image3.jpg

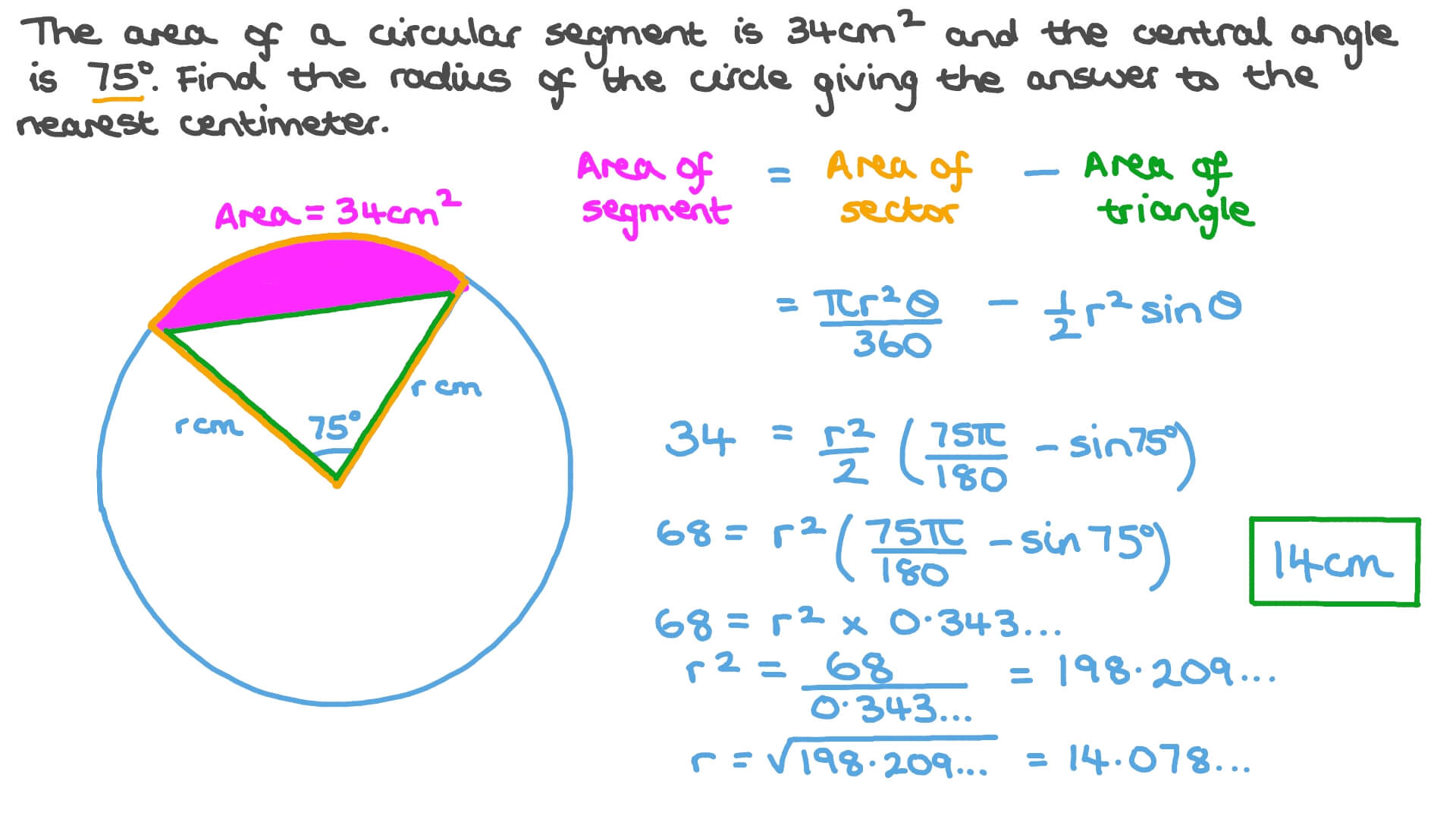

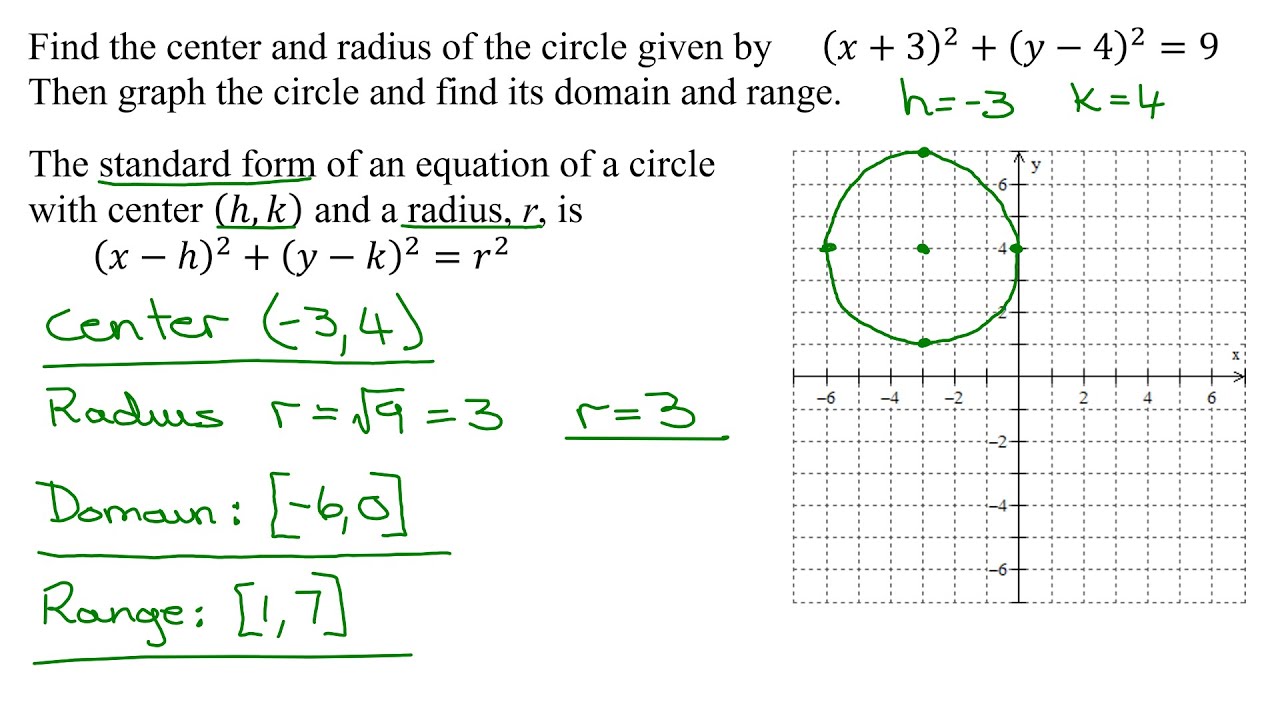

How To Find The Radius Of Circle How Do You Solve Chord Chords

https://i.ytimg.com/vi/auLfXuCqiLg/maxresdefault.jpg?sqp=-oaymwEmCIAKENAF8quKqQMa8AEB-AH-CYAC0AWKAgwIABABGGUgZShlMA8=&rs=AOn4CLDqBNfvyNo4Rm8L619vIQs-zk0Ddw

How Do You Find The Radius Of A Quarter Circle Find The Radius R

https://i.ytimg.com/vi/LY2Ypm7MIJc/maxresdefault.jpg?sqp=-oaymwEmCIAKENAF8quKqQMa8AEB-AH-CYAC0AWKAgwIABABGDAgTSh_MA8=&rs=AOn4CLBlalk0MfN81ykV5hNk5AGMz67wng

Calculate a pipe s bend radius using the curve s internal angle and the bend s length This calculator uses inches for measurements In V Groove bending the bend radius can be calculated with R V times alpha where V is the V die opening and alpha is the bending angle coefficient typically 0 33 for mild steel With a

For a 90 degree pipe turn multiply by four at this point Take the result of the calculation in Step 2 and call this value C Use the following equation to calculate the pipe A 90 degree bend will require more bend radius than a 45 degree bend Refer to the material data sheet of the steel type you are using for the recommended bend radius Use a standard equation to calculate the bend

More picture related to How To Find The Radius Of A 90 Degree Bend

The Blade Length Is The Radius Of The Circle Formed By The Area Swept

https://us-static.z-dn.net/files/da2/a9ba804b955f22325688dbd964099eb0.jpg

Solved The Long Chord Of A Compound Curve Is 250m And The Angle It

https://www.coursehero.com/qa/attachment/34341990/

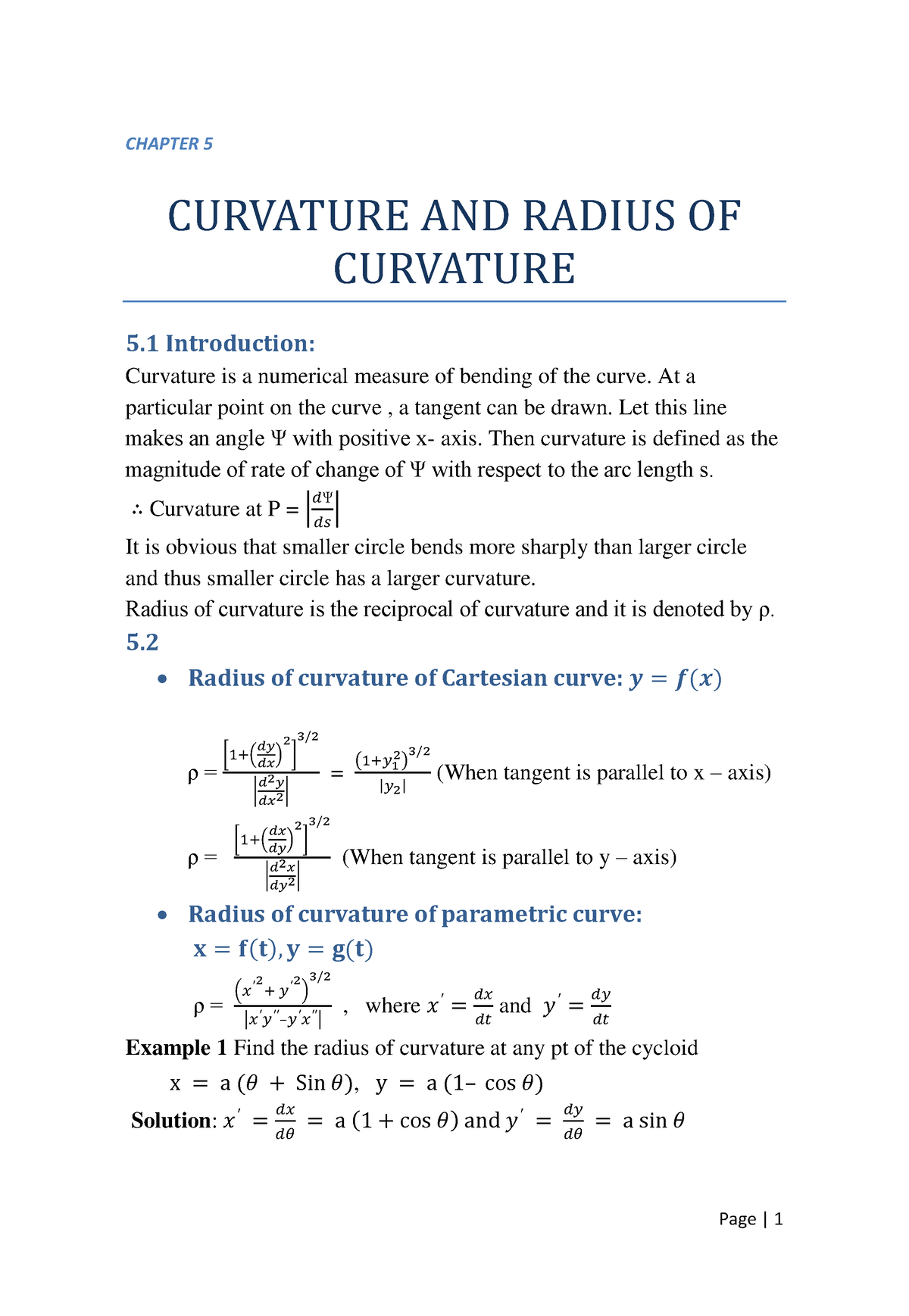

Radius of curvature Full File CHAPTER 5 CURVATURE AND RADIUS OF

https://d20ohkaloyme4g.cloudfront.net/img/document_thumbnails/87a279db4a682e7636ab5a387e9937b4/thumb_1200_1738.png

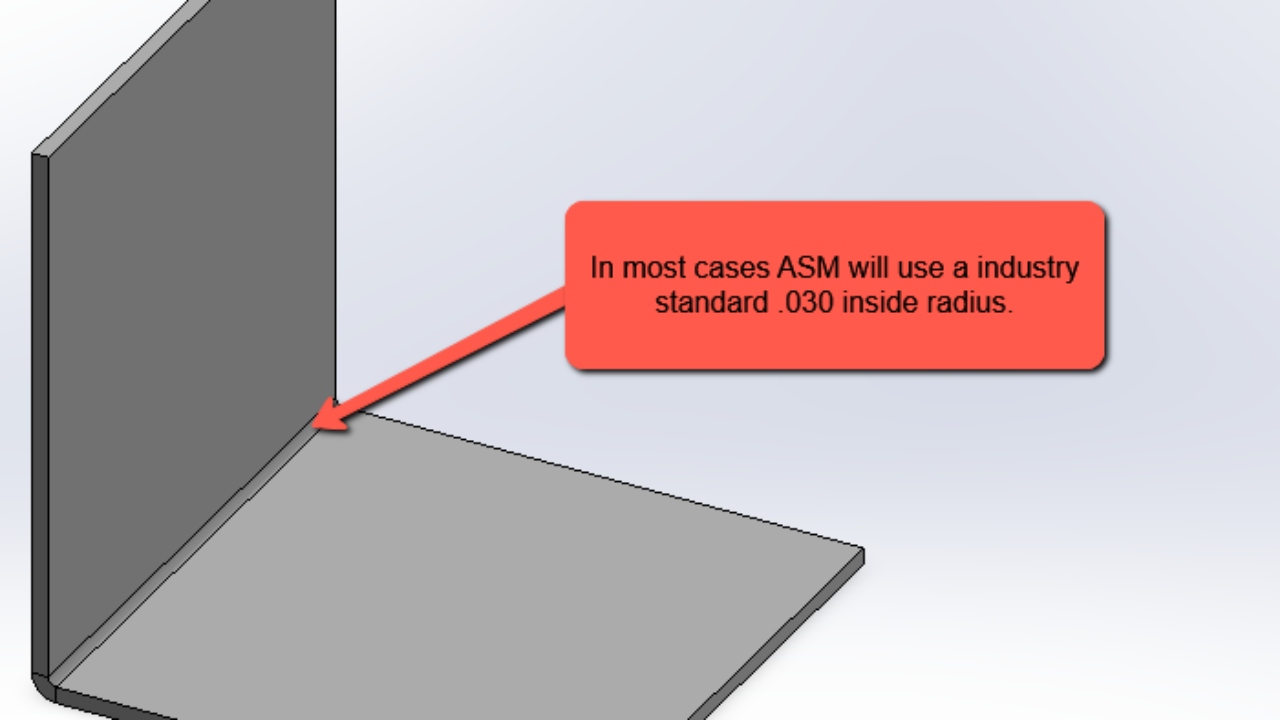

The radius of bend of a sheet of material is the radius of the bend as measured on the inside of the curved material The minimum radius of bend of a sheet of material is the sharpest curve or bend to which the sheet can be bent without The Bend Radius Calculator will compute the minimum bend radius based on the input parameters and material properties For a 2 0 mm thick aluminum sheet with a 90 degree

To calculate the radius produced at different bend angles first find the radius and length of the arc of the bend and then manipulate these results to factor in tensile and yield Enter the precise sheet thickness and desired inner bend radius The calculator will instantly provide the K factor Y factor and neutral layer position crucial for accurate

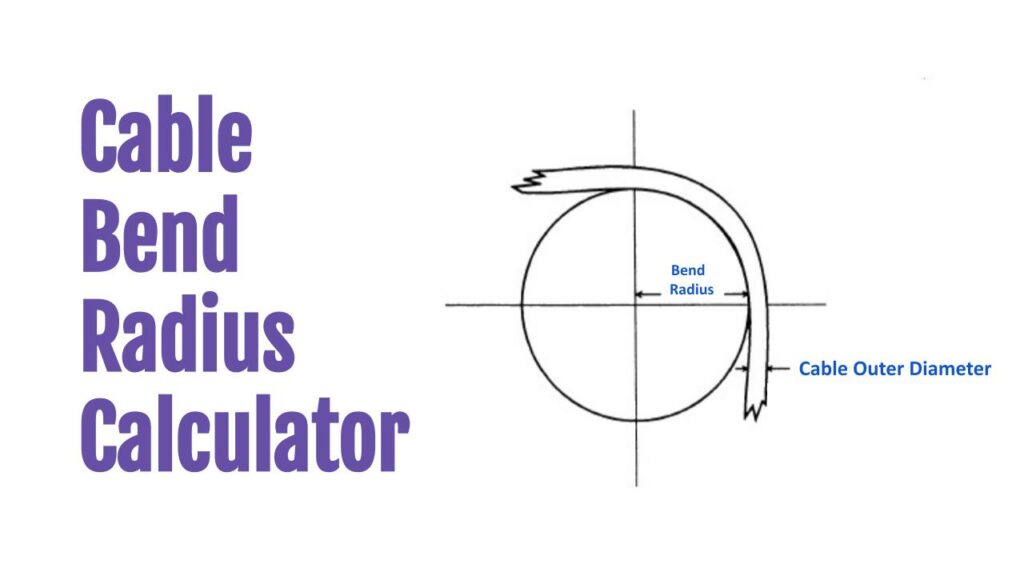

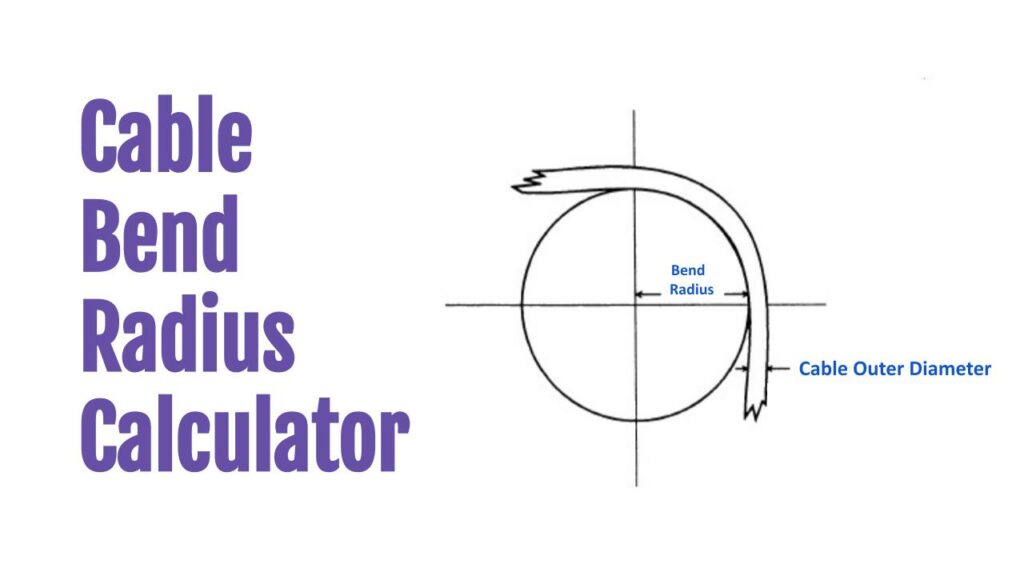

Cable Bend Radius Calculator

https://3roam.com/wp-content/uploads/2023/01/RF-Cable-Bend-Radius-Calculator-1024x576.jpg

How To Find The Radius Of A Circle

https://media.nagwa.com/676142056543/en/thumbnail_l.jpeg

https://www.javelin-tech.com › blog › ...

We are going to review three bending scenarios with three different bending angles 60 90 and 120 and we will calculate K Factor Bend Allowance and Bend Deduction for them The bending tool has a radius of 30 mm which

https://xometry.pro › en › articles › sheet-metal-bend...

Identify minimum flange length and achievable internal radius Find the minimum flange length suitable for the selected V opening as well as the achievable internal radius for this sheet

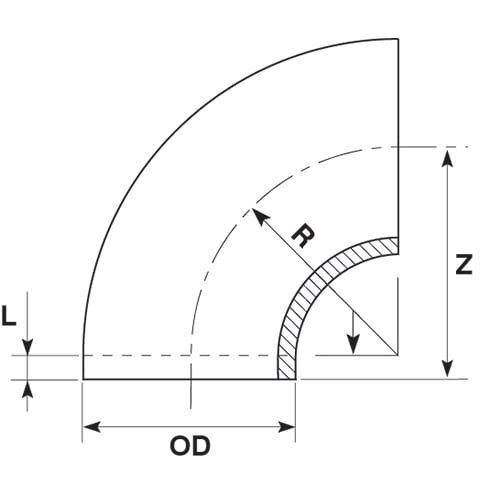

Short Radius Long Radius 10 To 90 Any Degree Elbow Center Formula

Cable Bend Radius Calculator

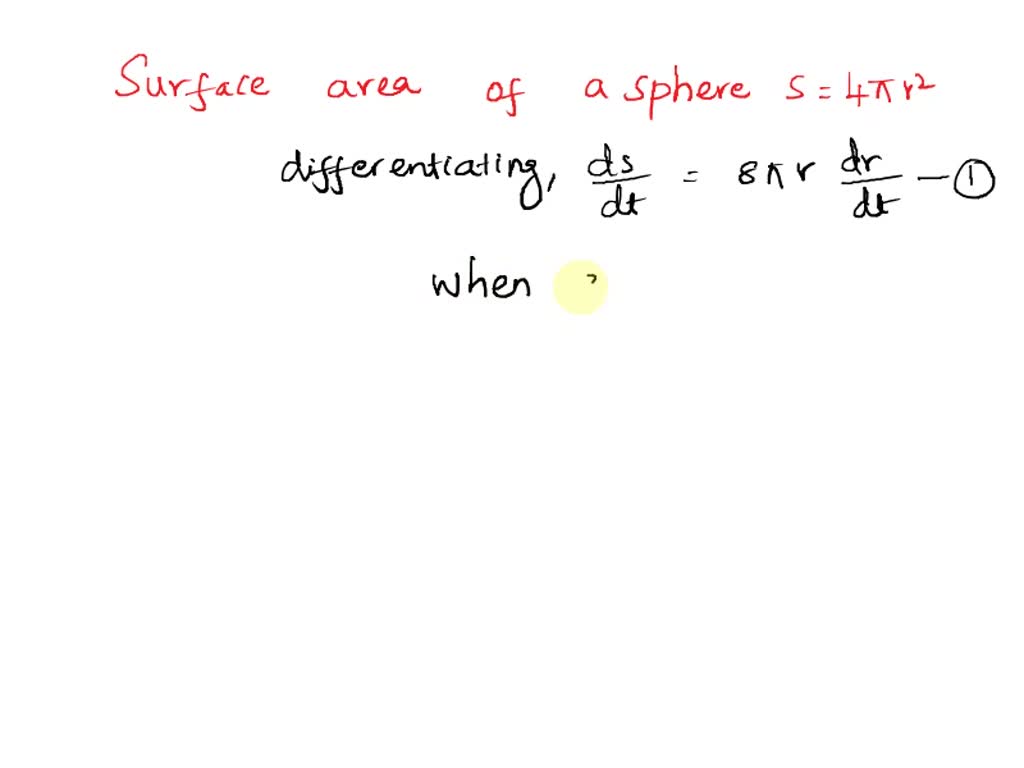

SOLVED area And The Radius Radius Of Are Sphere Numerically 5 Equal

Find Center Radius Of Circle Draw Graph Find Domain And Range YouTube

Elbow Schedule Chart

Python How To Find The Centre And Radius Of A Circle That Passes

Python How To Find The Centre And Radius Of A Circle That Passes

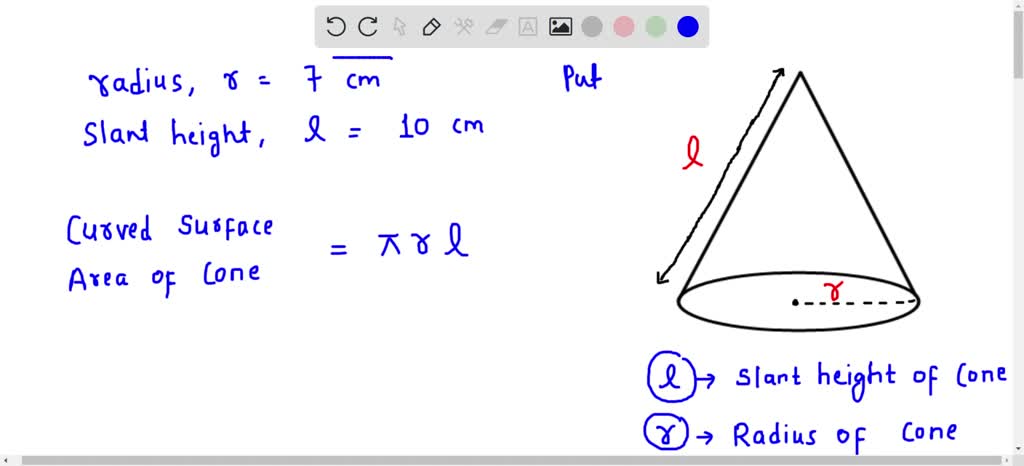

SOLVED 10 Calculate The Slant Height Of A Cone Whose Height Is 12 Cm

334 24 Bending Radius

How To Bend A Radius In Sheet Metal Unity Manufacture

How To Find The Radius Of A 90 Degree Bend - A 90 degree bend will require more bend radius than a 45 degree bend Refer to the material data sheet of the steel type you are using for the recommended bend radius Use a standard equation to calculate the bend